Copyright: isento GmbH

It’s official: the open source robot project pib (Printable Intelligent Bot) has been awarded the prestigious German Design Award 2025 – “Excellent Product Design” in the “AI in Product Design Processes” category. A great success in which I, Sebastian Glanzner, and my design office Glanzner Dynamics were able to play a key role.

My role in the pib project

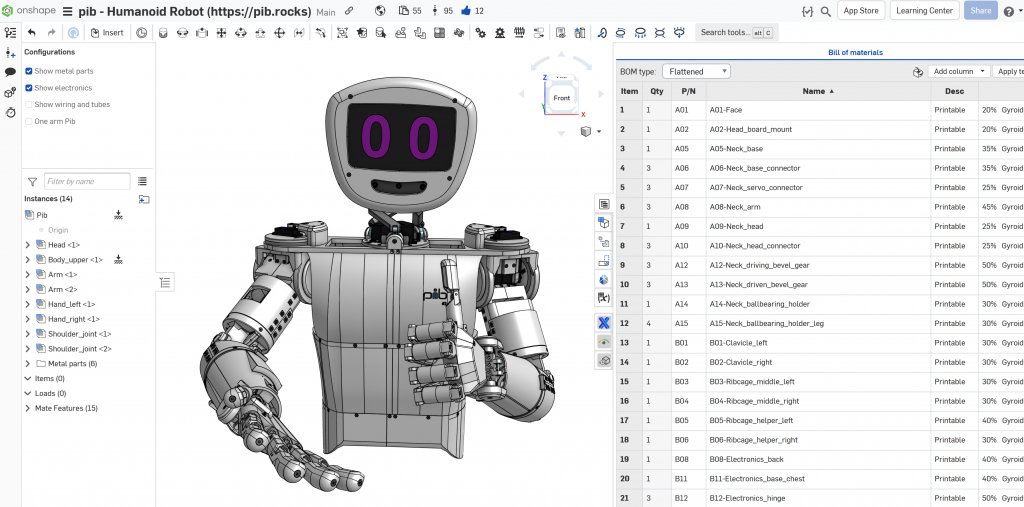

I have been supporting the pib project on a voluntary basis for two years and contribute my expertise as a CAD designer. As the person responsible for the mechanical design of the printable components, my goal was to take the design of the pib robot to a new level – with a clear focus on optimal manufacturability for commercially available FDM 3D printers.

CAD modelling: Optimized free-form surfaces

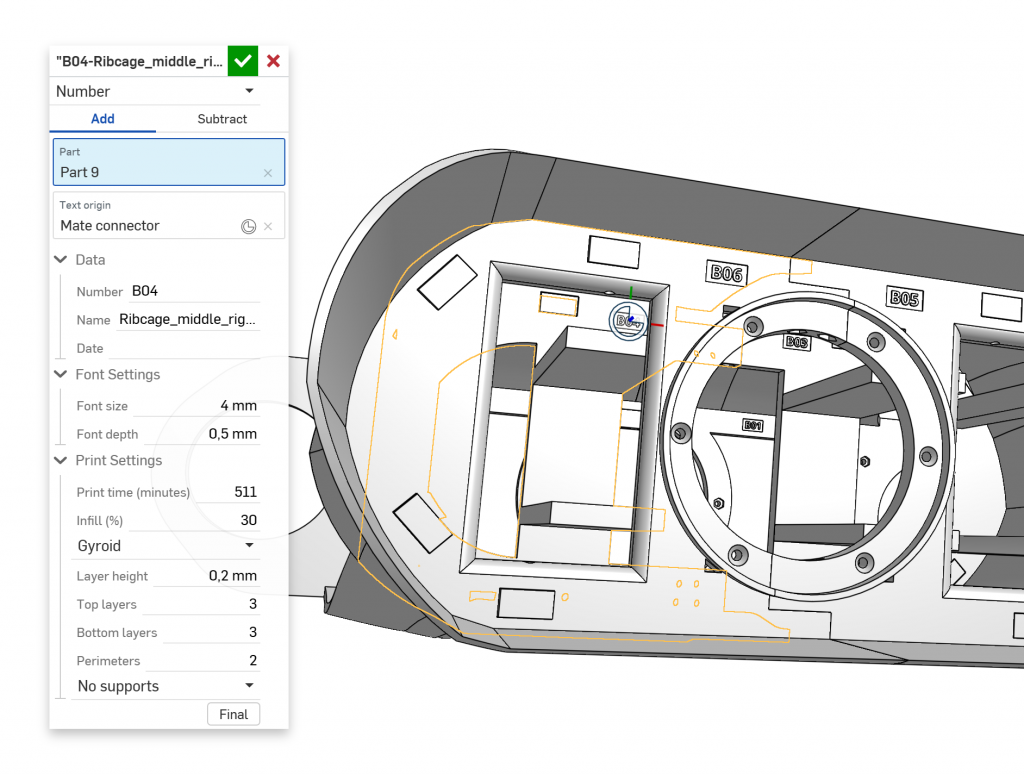

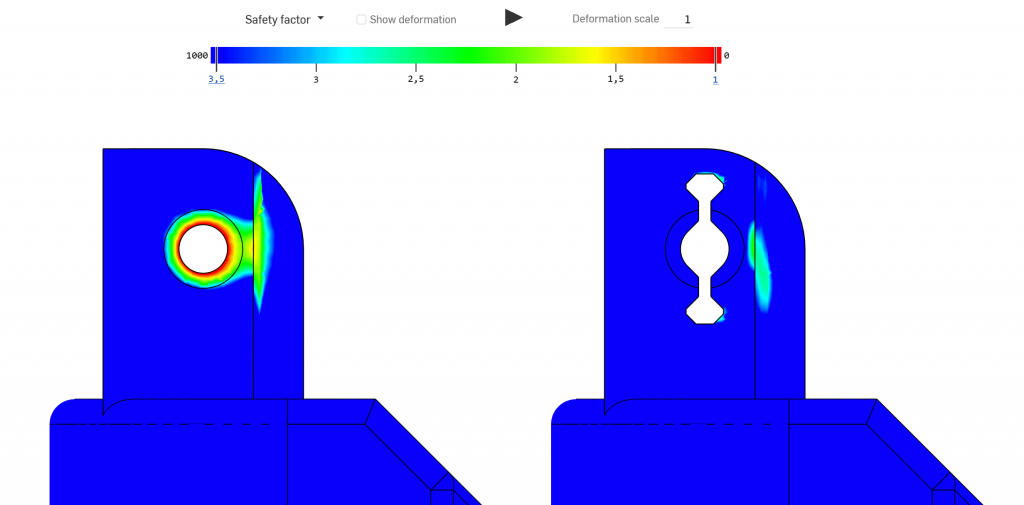

One of my biggest projects within pib was the comprehensive improvement of the robot’s upper body. Starting with a specially created master model, I first defined precise profile sections and derived flowing, organic free-form surfaces from them. The result is an aesthetic and ergonomically appealing upper body that is also functionally impressive.

Improvements to the neck and integrated cable management

In addition to the upper body, my focus was on optimizing the neck and shoulder joints. Targeted design changes made it possible to route the cables for the neck and head inside the robot. This innovation not only increases accessibility and the aesthetic appearance, but also makes the pib robot safer and more user-friendly overall.

Practical and easy-to-install design

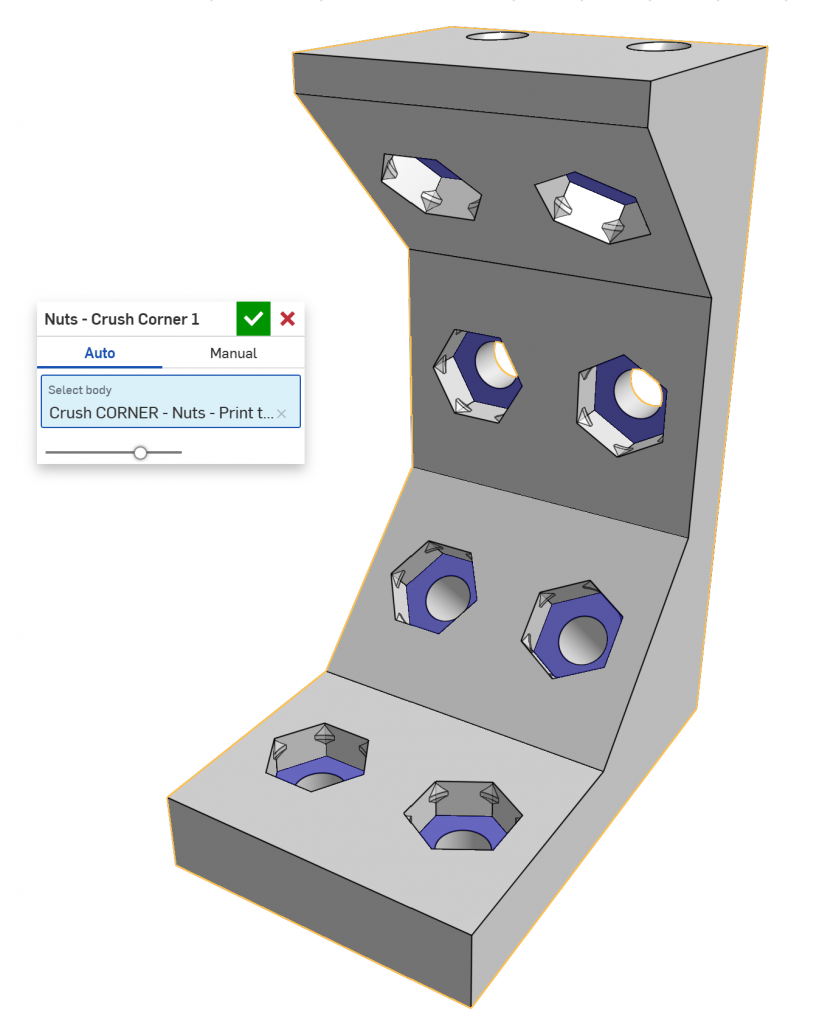

A key aspect of my CAD work was to make the assembly and maintenance of the robot as simple as possible. Each component is now clearly labeled and precisely designed to ensure intuitive and quick assembly. Small details such as integrated crush ribs for hexagon nuts and other 3D print-optimized press fits make assembly much easier.

pib as an ambassador for robotics, AI and 3D printing

What particularly drives me in my work is the vision behind the pib project: to give young people access to modern technology in a simple and inspiring way. pib brings topics such as robotics, artificial intelligence and 3D printing directly into the classroom – an inspiration for pupils to perhaps go down innovative paths themselves one day. Who knows, maybe a student who assembles and programs at pib today will found a new start-up in the field of humanoid robotics tomorrow?

Proud to be part of a vibrant community

Winning the German Design Award 2025 confirms the success of our joint efforts. As part of this inspiring community, I look forward to continuing to develop creative solutions and innovative designs for pib and other exciting projects with my design office.

You can find more information about the pib project at pib.rocks. If you have any questions about customized CAD solutions and other engineering projects, please contact Glanzner Dynamics.