Introduction:

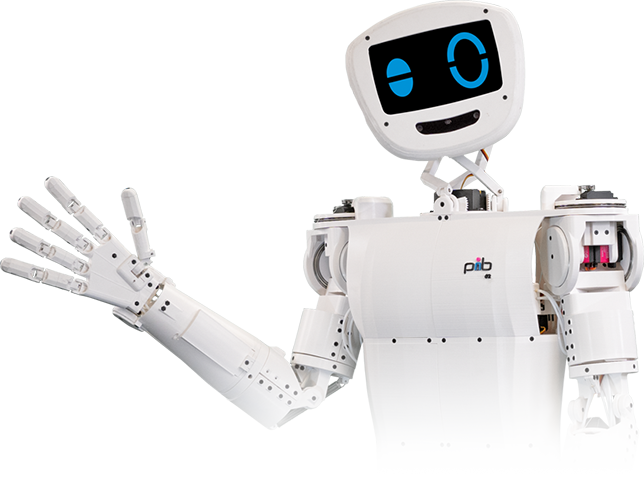

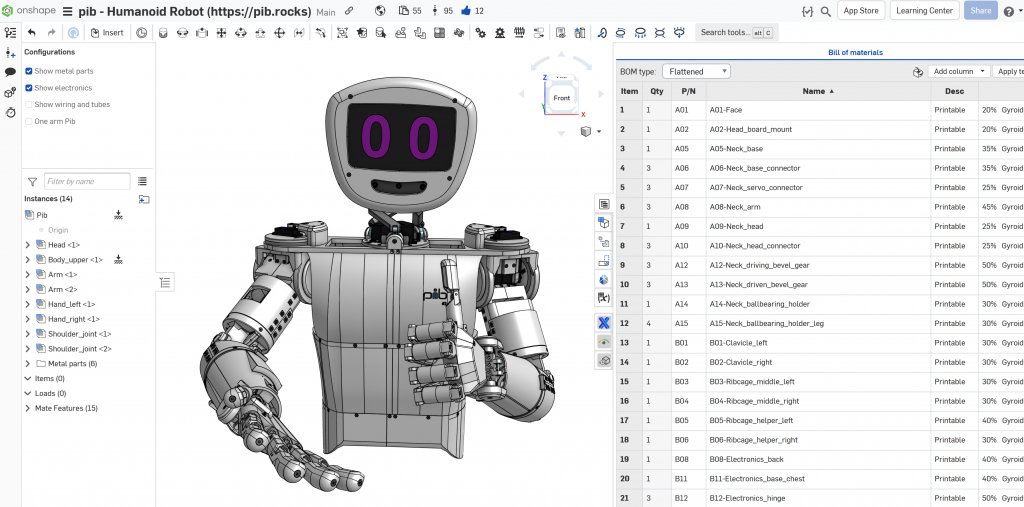

As a mechanical engineer with over 20 years of experience in CAD, I’ve always been passionate about creating and building innovative projects. Six months ago, I joined the open-source project pib (printable intelligent bot), initiated by isento GmbH. Pib is a 3D printable humanoid robot designed to make robotics accessible to everyone. In this blog post, I will share my experiences and contributions to the project.

Pib: An Open-Source Robotics Revolution:

Pib is a groundbreaking 3D printable humanoid robot that aims to engage people in the fields of robotics, 3D printing, and AI. The project’s website provides free 3D printing templates, assembly instructions, and a supportive community on Discord for collaboration and assistance.

My Contributions to pib:

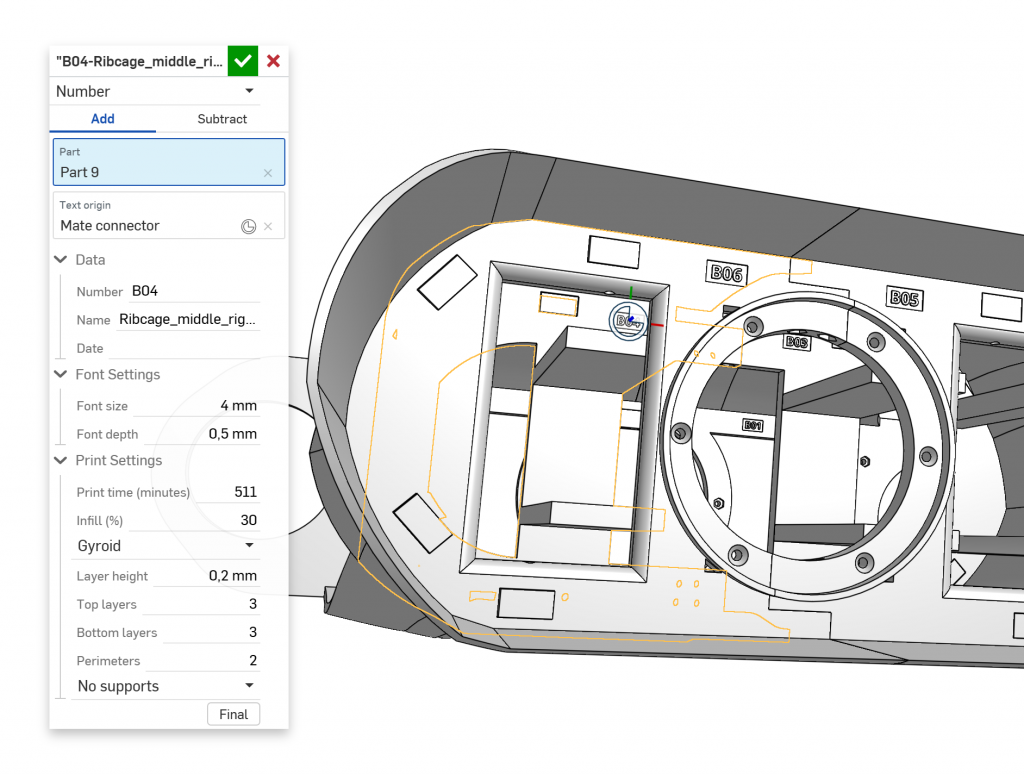

- FeatureScript for Part Number Imprints and Metadata:

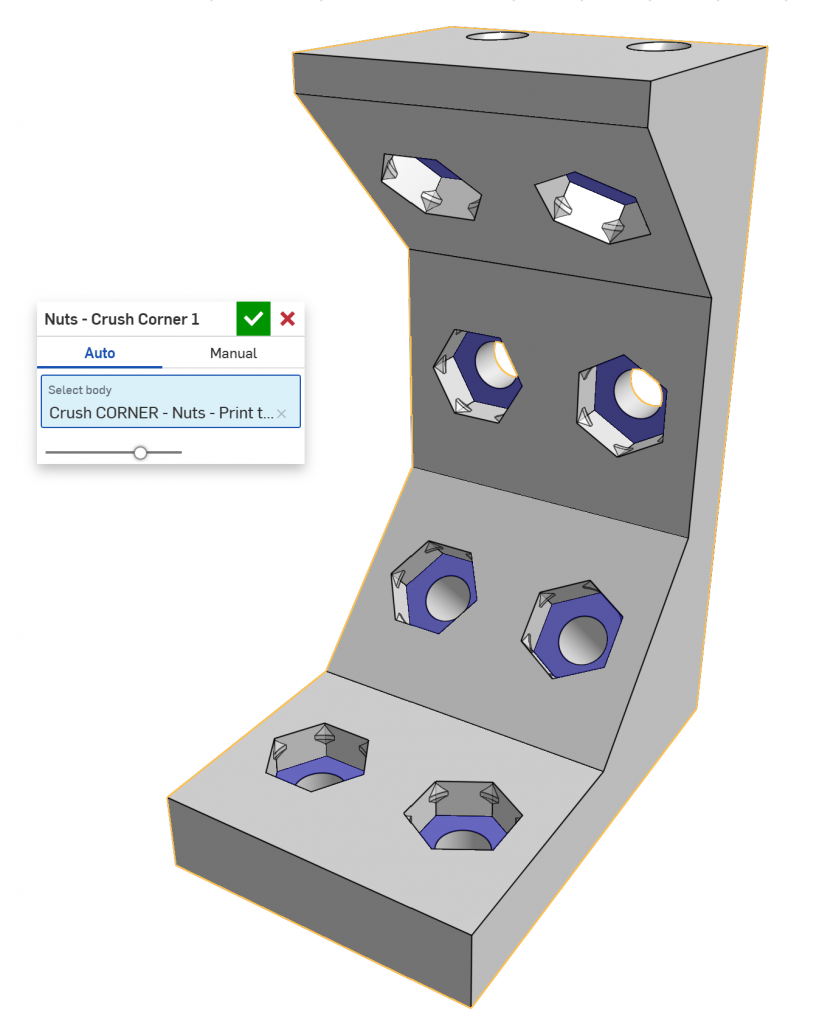

I developed a FeatureScript in Onshape to imprint the part number on each component. This script also inputs other data, such as print settings, which are then stored in the metadata of each part. - FeatureScript for Hexagonal Pockets and Crush Corners:

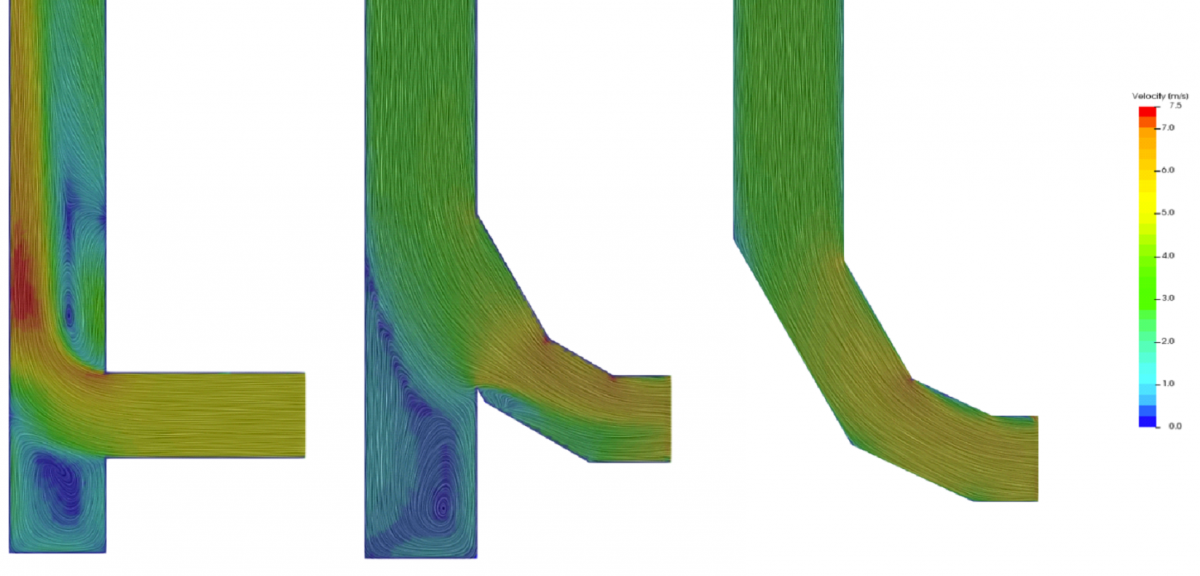

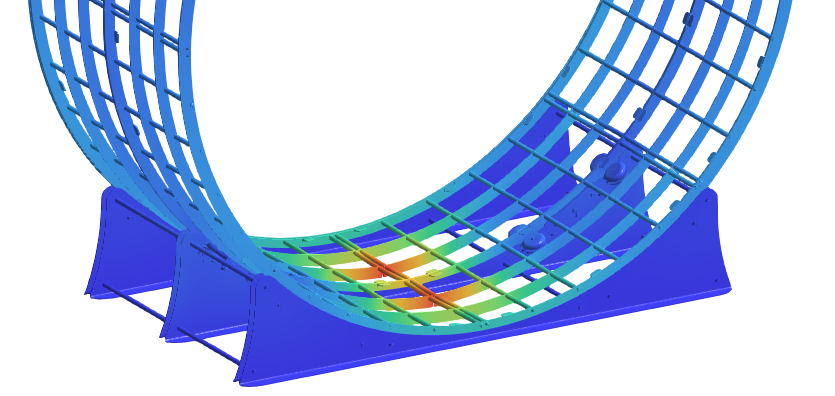

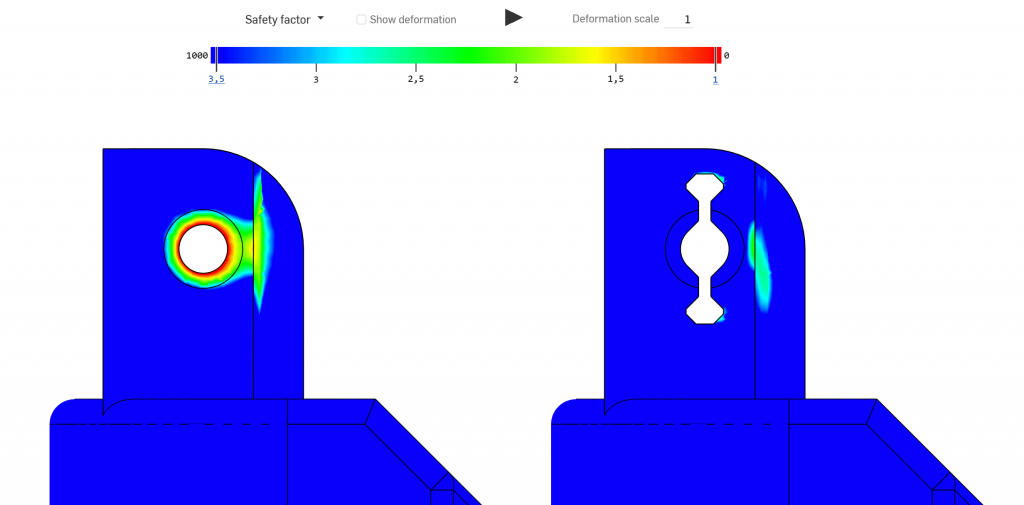

I’m currently perfecting a FeatureScript that detects all hexagonal pockets in a part and adds small “crush corners” to the hexagonal profile. This feature eases the holding of M3 nuts and simplifies pib’s assembly process. - Simulation for Flexible Press-Fits:

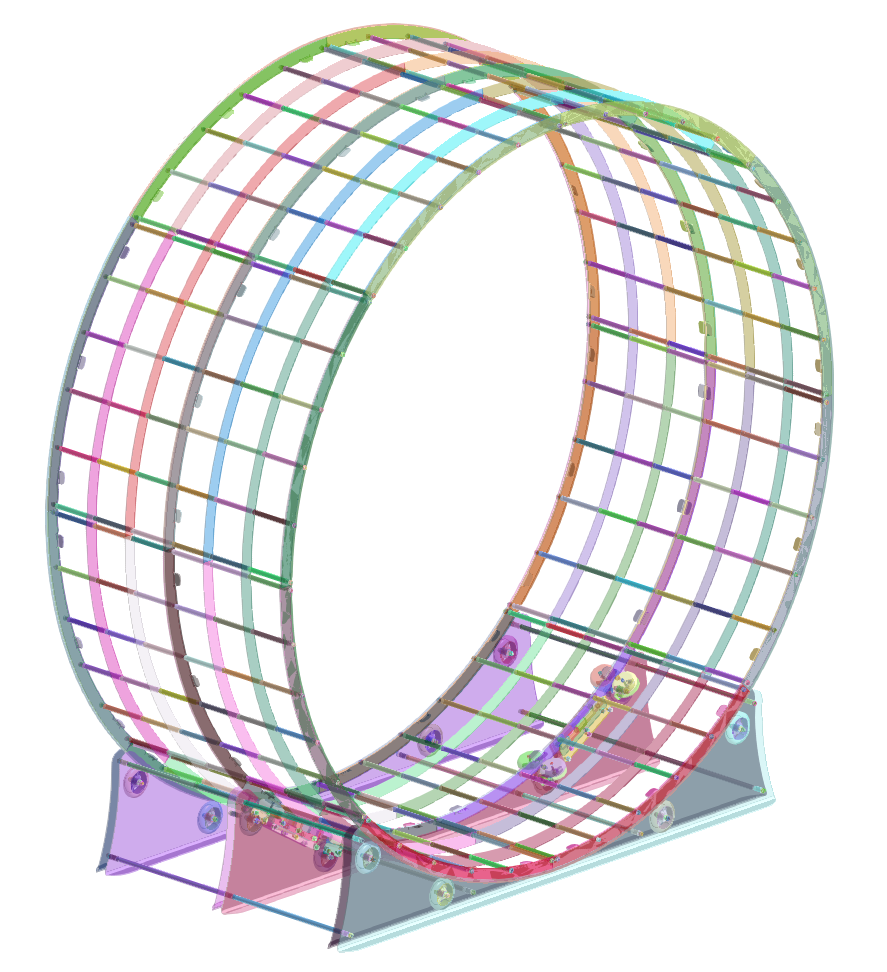

Utilizing Onshape’s built-in simulation tools, I designed flexible press-fits for the 2×20 metal rods. This improvement facilitated printing small holes to hold the rods without damaging the 3D printed parts during assembly. - Configurations for Part Visibility Control:

I contributed to integrating configurations that control part visibility, allowing users to choose whether to display only the printed parts or also show metal parts and electronics.

Pib@school: Inspiring the Next Generation of Innovators:

Pib@school is an educational initiative aimed at familiarizing students with robotics, 3D printing, and AI. This hands-on program introduces students to STEM topics and equips schools with packages for building and operating their own humanoid robots.

Join the pib Community:

If you’re interested in contributing to pib’s development or simply want to learn more about the project, join the pib community on Discord. Collaborate with like-minded individuals, share your ideas, and help shape the future of robotics.

Conclusion:

Pib is a pioneering project that leverages the power of Onshape to democratize robotics. As a mechanical engineer and a proud member of the pib community, I’m thrilled to be part of this journey and contribute to the development of the printable intelligent bot. Join us in building the future of robotics and exploring the potential of 3D printing and AI.